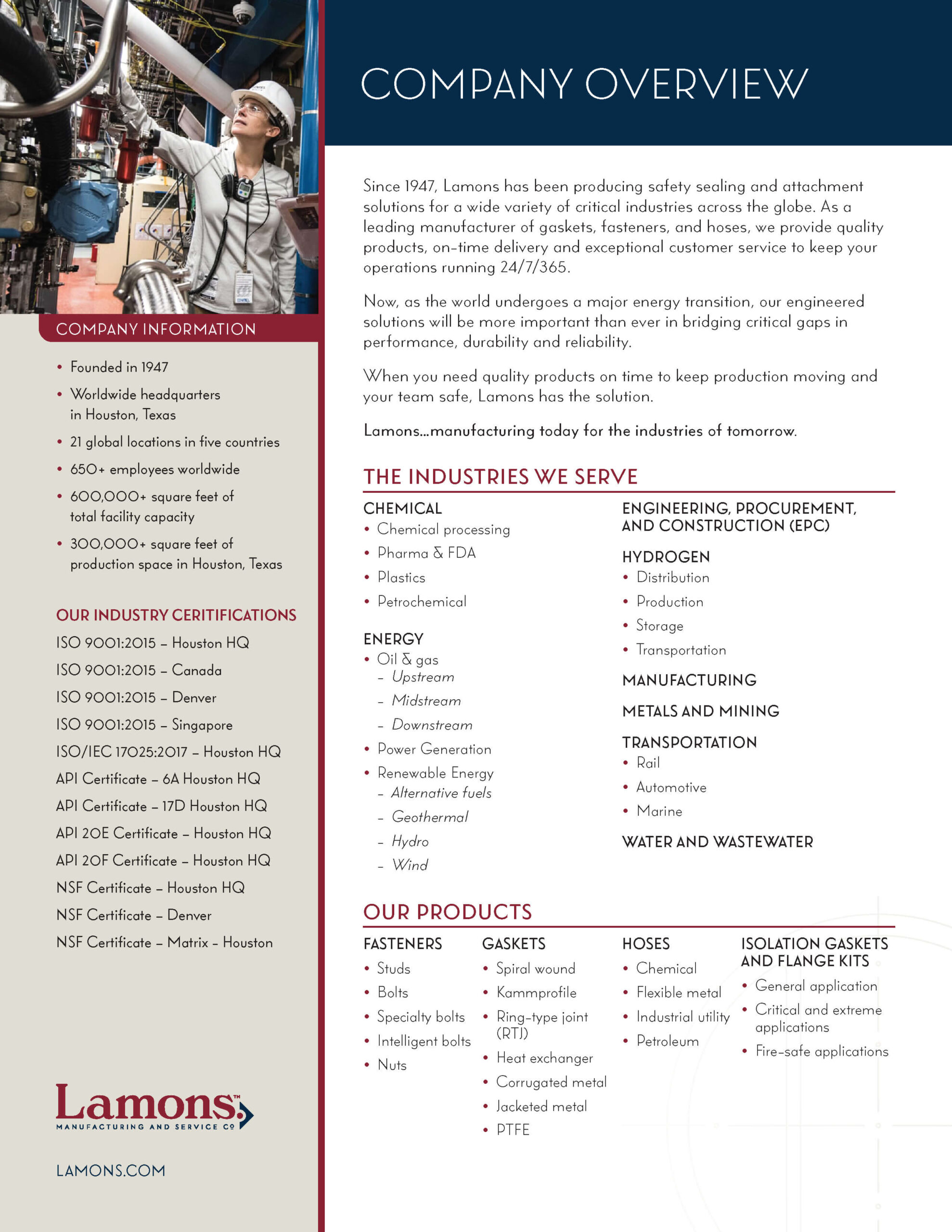

Since 1947, Lamons has been producing safety sealing and attachment solutions for a wide variety of critical industries across the globe. As a leading manufacturer of gaskets, fasteners, and hoses, we provide quality products, on-time delivery and exceptional customer service to keep your operations running 24/7/365.

Now, as the world undergoes a major energy transition, our engineered solutions will be more important than ever in bridging critical gaps in performance, durability and reliability. When you need quality products on time to keep production moving and your team safe, Lamons has the solution.

Lamons…manufacturing today for the industries of tomorrow.

Company Information

- Founded in 1947

- Worldwide headquarters in Houston, Texas

- 21 global locations in five countries

- 650+ employees worldwide

- 600,000+ square feet of total facility capacity

- 300,000+ square feet of production space in Houston, Texas

The Industries We Serve

Chemical- Petrochemical

- Chemical Processing

- Pharma & FDA

- Plastics

Energy

- Oil & gas

- – Upstream

- – Midstream

- – Downstream

- Power Generation

- Renewable Energy

- – Alternative fuels

- – Geothermal

- – Hydro

- – Wind

Hydrogen

- Distribution

- Production

- Storage

- Transportation

Manufacturing

Metals and Mining

Transportation

- Rail

- Automotive

- Marine

Water and Wastewater

Our Industry Certifications

ISO 9001:2015 – Houston HQ

ISO 9001:2015 – Canada

ISO 9001:2015 – Denver

ISO 9001:2015 – Singapore

ISO/IEC 17025:2017 – Houston HQ

API Certificate – 6A Houston HQ

API Certificate – 17D Houston HQ

API 20E Certificate – Houston HQ

API 20F Certificate – Houston HQ

NSF Certificate – Houston HQ

NSF Certificate – Denver

NSF Certificate – Matrix – Houston

Our Products

Fasteners

• Studs

• Bolts

• Specialty bolts

• Intelligent bolts

• Nuts

Gaskets

• Spiral wound

• Kammprofile

• Ring-type joint

(RTJ)

• Heat exchanger

• Corrugated metal

• Jacketed metal

• PTFE

Hoses

• Chemical

• Flexible metal

• Industrial utility

• Petroleum

Isolation Gaskets and Flange Kits

• General application

• Critical and extreme

applications

• Fire-safe applications

Lamons Services and Technology Offerings

TruFASTTM Re-engineering Services

Our Field Acquired Seal Technology® is a custom engineering process that reproduces undocumented gaskets. By simply providing a picture of an old gasket or a flange rubbing, our engineering team, working with manufacturing, can produce a replacement gasket. Our TruFAST re-engineering services often shortens the reproduction process from weeks or days to hours.

Engineered Solutions

The Lamons engineering team provides custom, engineered solutions that deliver the right product for your application. Our products are highly reliable, expertly produced safety sealing and attachment solutions, and our extensive inventory of raw materials (including centrifugal castings, forgings, and plates) allows us to respond quickly to your projects.

Field Support

With 21 global locations, our team is ready to assist you with troubleshooting, torque calculations, failure investigations, on-site support, bolt-up protocols, critical gasket recommendations, expert field measurements, and much more.

Specialty Machined Parts

Lamons maintains over 30 state-of-the-art CNC machines. Our programmers and machinists deliver high-quality, machined components with one of the quickest response times in the industry.

Value-added Benefits

Lamons provides smart technology solutions to help keep you up and running 24/7/365:

- eCatalog eCommerce Solutions – An advanced, highly customizable online shopping catalog that integrates seamlessly with your material requirements planning (MRP) and enterprise resource planning (ERP) systems.

- Drawings Online Repository – Paper drawings converted to electronic files with pertinent details including unit and equipment unique identifiers, kitting of components, part numbers, equipment specifics, required quantities, mechanical details for gaskets, and more. Drawings online can also create custom packing slips and detailed labels.

- Inventory Management System – Rely on Lamons for on-site inventories of your routine parts. Whether inventories are owned or on consignment, you can manage inventory levels, replenish stock, and track material receipts and shipments with our web-based system. Simplify the purchase process even further by integrating our vendor-managed inventory with your ERP system.

- Asset Tracking and Preventive Maintenance System – A desktop and mobile application that allows you to manage your purchased assets, assign unique tracking numbers, save and recall asset-specific documents, define preventive maintenance periods, and more.

To learn more about how Lamons can support your operations, visit our website.

To contact our engineering team directly, email: [email protected].