Sealing/Isolating Gaskets and Flange Isolation Kits

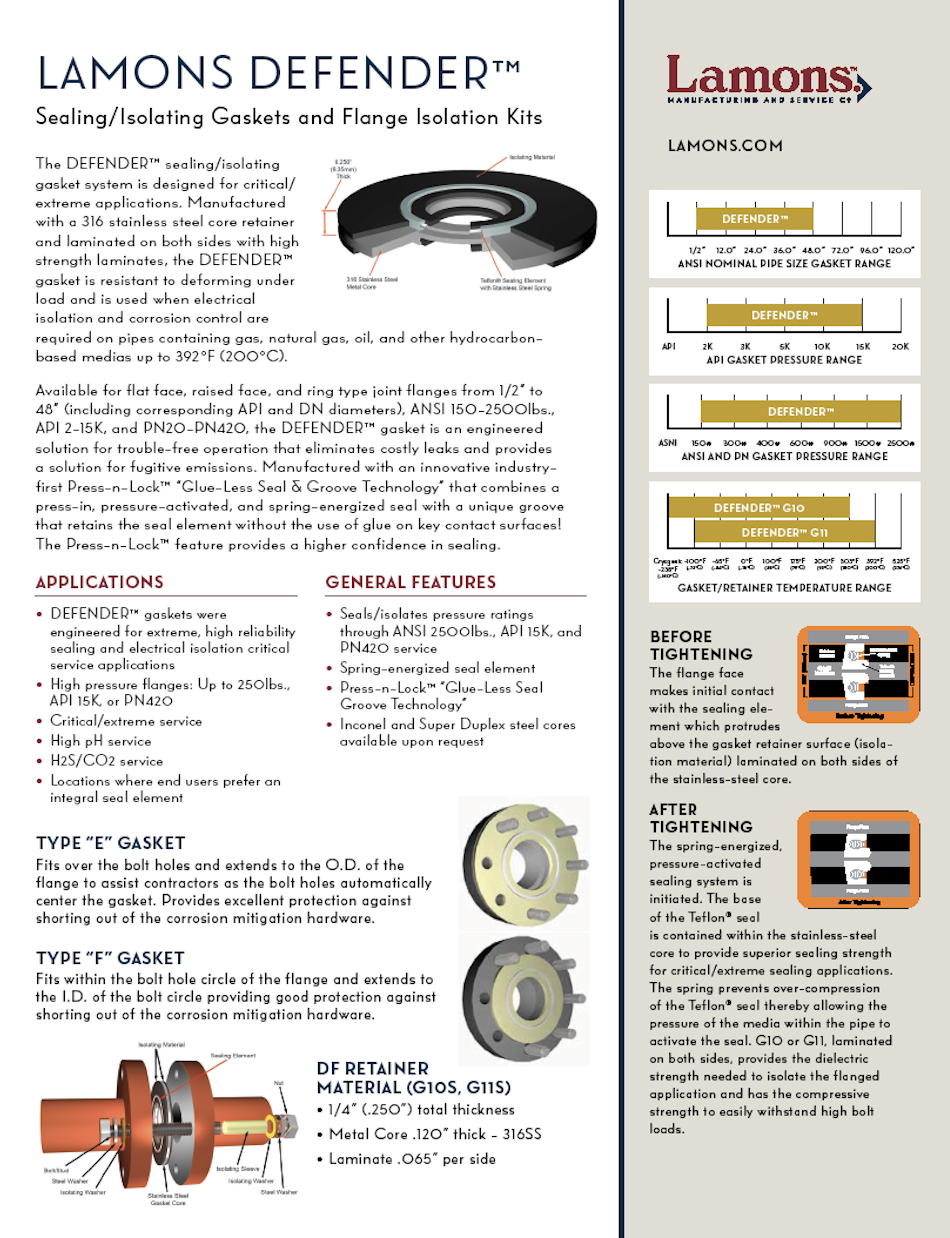

The DEFENDER™ sealing/isolating gasket system is designed for critical/extreme applications. Manufactured with a 316 stainless steel core retainer and laminated on both sides with high strength laminates, the DEFENDER™ gasket is resistant to deforming under load and is used when electrical isolation and corrosion control are required on pipes containing gas, natural gas, oil, and other hydrocarbon-based medias up to 392°F (200°C).

Available for flat face, raised face, and ring type joint flanges from 1/2” to 48” (including corresponding API and DN diameters), ANSI 150-2500lbs., API 2-15K, and PN20-PN420, the DEFENDER™ gasket is an engineered solution for trouble-free operation that eliminates costly leaks and provides a solution for fugitive emissions. Manufactured with an innovative industry-first Press-n-Lock™ “Glue-Less Seal & Groove Technology” that combines a press-in, pressure-activated, and spring-energized seal with a unique groove that retains the seal element without the use of glue on key contact surfaces! The Press-n-Lock™ feature provides a higher confidence in sealing.

Applications

- DEFENDER™ gaskets were engineered for extreme, high reliability sealing and electrical isolation critical service applications

- High pressure flanges: Up to 250lbs., API 15K, or PN420

- Critical/extreme service

- High pH service

- H2S/CO2 service

- Locations where end users prefer an integral seal element

General Features

- Seals/isolates pressure ratings through ANSI 2500lbs., API 15K, and PN420 service

- Spring-energized seal element

- Press-n-Lock™ “Glue-Less Seal Groove Technology”

- Inconel and Super Duplex steel cores available upon request

Type “E” Gasket

Fits over the bolt holes and extends to the O.D. of the flange to assist contractors as the bolt holes automatically center the gasket. Provides excellent protection against shorting out of the corrosion mitigation hardware.

Type “F” Gasket

Fits within the bolt hole circle of the flange and extends to the I.D. of the bolt circle providing good protection against shorting out of the corrosion mitigation hardware.

DF Retainer Material (G10S, G11S)

- 1/4” (.250”) total thickness

- Metal Core .120” thick – 316SS

- Laminate .065” per side

DFT Retainer Material (G10S, G11S)

- 0.314” total thickness

- Metal Core 0.250” thick – 316SS

- Laminate 0.032” per side

Seal Element Materials

- PTFE (Teflon®) Spring-Energized Spring is stainless steel

- Nitrile

- Viton®

Facts

- Proven design based on the industry leader

- Enhanced with innovative engineered features

- Tested to Shell Certification Standards

- Industry First! The Press-n-Lock™, “Glue-Less Seal Groove Technology,” an engineered design, has significant sealing advantages versus other brands

- Made in the USA

Industries (Oil, Gas)

- Production Fields

- Petroleum Marketing Facilities

- LNG/SNG Systems

- Pipeline and Distribution Piping

- Refineries

DEFENDER™ Flange Isolation Kits

For a flange isolation kit, sleeves and washers are needed. Generally, 95% of steel core gasket flange isolation kits (DEFENDER™ Kits) are sold with G10 sleeves and G10 double washer sets.

Suggested Sleeve/Washer Sets

SD = Standard (G10 sleeves, steel ZP washers and G10 washers) – double washer set.