Non-Metallic

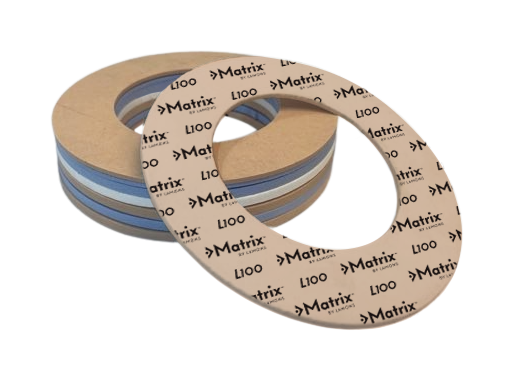

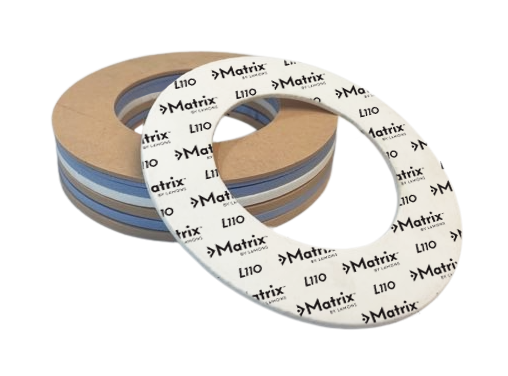

Non-MetallicMatrix Biaxially Orientated PTFE Sheet Gaskets

PTFE gaskets are resistant to temperature extremes from cryogenic to 500°F (260°C) as well as resistant to chemicals, solvents, caustics and acids except free fluorine and alkali metals. PTFE gaskets can be supplied in a variety of forms; either as virgin or reprocessed material, and also with a variety of filler materials to inhibit cold flow or creep relaxation. Our range of biaxially oriented PTFE materials (L100, L104, L110) feature biaxial orientation of the PTFE particles that creates a unique strength in both longitudinal and transverse directions. This superior matrix orientation and addition of premium fillers allows the material to resist creep and cold flow when subject to load.

L100 (Fawn)

This biaxially orientated high-quality silica-filled PTFE sheet is effective for use in sealing most chemicals except molten alkali metals, fluorine gas, and hydrogen fluoride. This material is approved for potable water service, complies with requirements of FDA regulations, and can be used at all concentrations of sulfuric acid.

L104 (Blue)

This superior performance, biaxially orientated sheet material contains PTFE and hollow glass microspheres for use in sealing most chemicals except molten alkali metals, fluorine gas and hydrogen fluoride. This material is approved for potable water service, complies with requirements of FDA regulations, and has exceptional compression characteristics making it effective for use in glass lined flanges or where loading problems exist.

L110 (Off White)

This pigment-free biaxially orientated barium sulfate-filled PTFE sheet provides superior performance for use in sealing food, pharmaceuticals, and other general chemical media. This material complies with requirements of FDA regulations and is acceptable for use in aqueous hydrofluoric acid below 49%, but is not suitable for sealing molten alkali metals or fluorine gas.